The Design

Compact with lots of technology in it

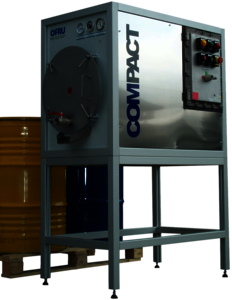

We have developed the distillation unit COMPACT as a successor model to the successful DSC plant series. It combines in a small space technology and components as we know them from our large plants. The evaporator chamber is extra small with a volume of 70 litres and suitable for continuous distillation.

Workmanship

Each plant a single piece

Our production team builds according to customer requirements and high quality standards. Depending on the distillation units configuration, this small system for solvents can be supplemented with features and equipment features to guarantee a complex preparation process. Ultimately, each system is unique and manufactured with special attention and precision.

Safety

Safety on the basis of large-scale plants

There is no compromise here. The German requirements for the development of such a plant are very strict. Therefore this plant does not only own a justified CE mark but is built according to the ATEX guidelines. In cooperation with TÜV we document the production according to RL 2014/34/EU**.

For 40 years we have been your good partner in the field of solvent processing. Well-known companies trust in us and use COMPACT successfully.

Function

Automatic operation

The explosion-proof distillation unit COMPACT fills automatically from a dirt barrel and replaces the known batch plants, which are usually filled only once a day or in cycles only. This small plant has a horizontal stainless steel distillation vessel, which can be easily cleaned after recovery process.

A dirt container in the form of a bucket or barrel is connected to the plant. The distillation unit fills fully automatically, unattended and with intelligent automatic shut-off. During continuous preparation, the clean solvent flows out automatically on the left side of the system. An empty drum or tank can collect the purified solvent.

| Technical data | COMPACT 6 kW without vacuum | COMPACT 6 kW with vacuum |

| Boiler/Vessel volume | 70 l | 70 l |

| Constant filling volume, level controlled | 35 l | 35 l |

| Distillation rate approx. | 7-20 l/hr* | 7-20 l/hr* |

| Heat-up time approx. | 0.5 hr* | 0.5 hr* |

| Heating temperature | Max. 200 °C | Max. 200 °C |

| Vacuum abs. (optional) | Max. 50 mbar | Max. 50 mbar |

| Voltage | 380-410 V / 50 Hz / 3 Ph + N | 380-410 V / 50 Hz / 3 Ph + N |

| Power consumption thermal oil heating | 6 kW | 6 kW |

| Power consumption vacuum unit (opt.) | - | 1,1 kW |

| Compressed air consumption approx. | 6 bar, Max. 50 l/min. | |

| Useful cooling capacity requirement approx. | 4 kW | 4 kW |

| Cooling water consumption (8-12° C) approx. | 0.5 m³/hr | 0.5 m³/hr |

| Width x depth x height approx. | 0,80 x 1,30 x 1,60 | 1,30 x 1,30 x 1,60 |

| Weight approx. | 140 kg | 200 kg |

The explosion-protected solvent distillation unit COMPACT is the smallest solvent distillation unit from OFRU, which works with automatic filling. The plant is designed for approx. 60-400 l/day and consists of a thermal oil heated horizontal distillation vessel made of stainless steel, in which the contaminated solvent is treated.

The solvent distillation unit COMPACT operates fully automatically and fills automatically and continuously by means of an integrated double diaphragm pump or the vacuum option.

The solvent distillation unit is filled at regular intervals from a storage tank / dirt drum. A level controller keeps the level continuously constant in the distillation vessel and enables almost unattended operation, if necessary in 24-hour operation.

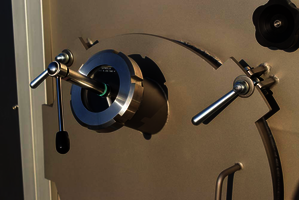

Display units in the front panel provide information on the boiling/steam temperature of the solvent, the process pressure in the solvent distillation unit vessel and the nominal/actual values of the heating. The electrical control system monitors all safety-relevant parameters and switches the plant off automatically in the event of a fault. For example, the automatic filling system detects when the dirty barrel is empty. The SIEMENS control system then automatically switches over to "sump distillation" and thickens the distillation residues to a specified viscosity (adjustable by timer). The solvent distillation unit then stops automatically and is ready for emptying via the large boiler door.

The solvent distillation units COMPACT is equipped with an ATEX-tested Ex switch cabinet and contains high-quality electrical components. Operation is extremely user-friendly and safe. The vacuum option is available for high-boiling solvents >150 °C boiling point. This option includes a high-performance vacuum pump that generates a vacuum down to -0.95 bar. In the solvent distillation unit the boiling temperature of the solvents is thus greatly reduced and the heating temperature can be set lower.

The installation and commissioning of the solvent distillation unit can be carried out within a short time. All connections are located on one side of the system. A dirt drum and a clean drum are connected there

Solvent distillation unit COMPACT - the manual pouring of solvents is a thing of the past.

- Automatic mode: Automatic and continuous filling with contaminated solvents: No more pouring!

- Fill level is kept constant, thus largely constant distillation capacity

- Lying/horizontal distillation vessel made of stainless steel: Easy emptying and cleaning, no tilting of the plant necessary, no more expensive bags

- Small distillation vessel of 70 liters volume: Fast heating of the solvent, high distillation capacity possible with small size

- Water cooling: Optimum condensation of solvent vapours even at high ambient temperatures

- Integrated ATEX/EX control cabinet with digital SIEMENS control

- Auto-Stop: When the dirty barrel is empty, at temperature errors, when no thermal oil is present, when no cooling water is present

- Constructed according to the latest European directives: Operational safety at a high level

* Depends on type and composition of solvent, type and proportion of contamination, heating temperature, vacuum, cooling water pressure and temperature, boiling behaviour.

**Accompanying depot point acc. to RL 2014/34/EU