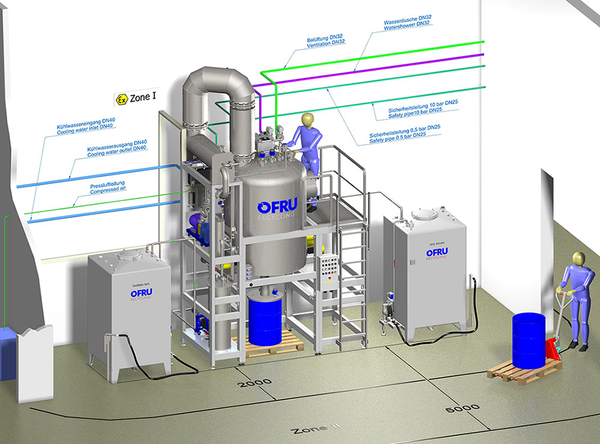

Solvent Distillation Plants ASC-1500 48 kW

Functional description of the solvent distillation plants

The ASC-1500 48 kW is an extremely comfortable vacuum solvent distillation plant from the professional ASC series. It has a modern integrated steam heating.

Heating of solvent distillation plants ASC-1500

A special feature of the solvent distillation plants are the conical stainless steel distillation vessel or boiler, in which the shell surface is heated with steam. The solvent distillation plants heating steam in the double jacket transfers the heat extremely quickly to the solvent. At the same time, high distillation performance is achieved with a small boiler volume.

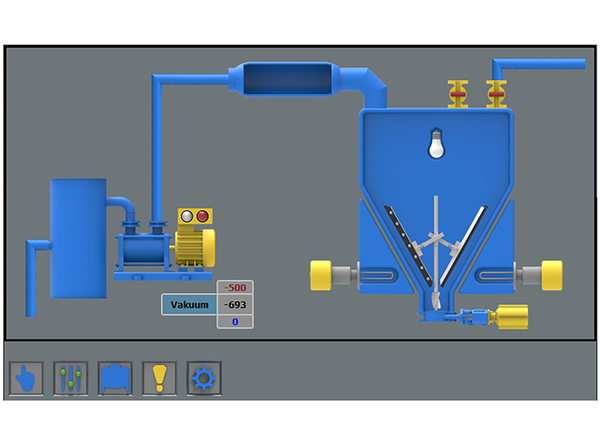

The ASC solvent distillation plants have a clever design. Only one electrical connection is required for the integrated steam heating of the solvent distillation plants. A high performance liquid ring vacuum pump conveys the dirt into the solvent distillation plants and guarantees continuous 24 hour operation. During automatic distillation in the distillation plants, the evaporated amount of solvent is automatically replenished by the addition of dirt into the solvent distillation plants. This automatic continuous distillation mode can be set by timer.

Solvent distillation plants safety function:

If the dirt tank of the customer contains no more solvent, the solvent distillation plants receive a signal and automatically switches to "sump distillation". The continuous filling into the solvent distillation plants is stopped and the amount of solvent still present in the solvent distillation plants boiler is evaporated until the dirt becomes a thick concentrate. The solvent distillation plants then switches off and is ready for manual or fully automatic emptying.

The distilled or purified solvent flows continuously from the solvent distillation plants into the customer's on-site tank.

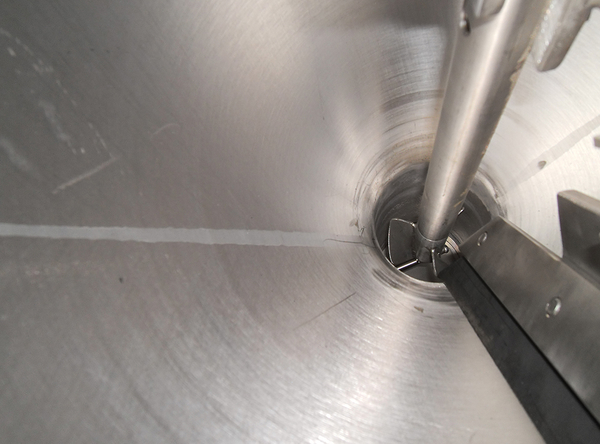

Perfect scraper system in ASC-1500 solvent distillation plants

A further feature of the ASC solvent distillation plants is a slow-running scraper agitator with automatically adjusting doctor blade made of PTFE. This unique doctor blade (scraper) system has been further developed over 30 years and is now used in our solvent distillation plants for its robustness and cleaning efficiency. Two strong scrapers made of PTFE optimally clean the conical evaporator vessel in the solvent distillation plants and do not have to be readjusted. The doctor blades or scrapers clean the boiler wall over the entire filling area and not only at the boiler bottom like other solvent distillation plants.

The contact pressure on the steep walls is optimal and large enough to prevent the build-up of deposits in solvent distillation plants.

Flexible process in solvent distillation plants and adaptation to customer requirements:

The entire solvent distillation process for the solvent distillation plants is controlled by a SIEMENS SPS S7 1200. If the local requirements of the customer change due to tanks, pumps or processes, the Siemens control system can be reprogrammed at any time and adapted to customer requirements for the solvent distillation plants integration. And this in national language bps. Chinese, Russian etc.! OFRU solvent distillation plants are multi-language ready.

Discharging the distillation residues in ASC solvent distillation plants:

The viscous solvent residues in the solvent distillation plants are emptied by gravity via a slide valve at the lowest point of the conically round boiler. The solvent distillation plants can then be automatically refilled with contaminated solvent. A new continuous distillation process of solvents begins.

| Technical Data | ASC-1500 48 kW kW with Vacuum |

| Boiler volume | 1500 l |

| Constant filling volume, level controlled | ~ 800 l |

| Distillation capacity approx. | 120-300 l/hr* |

| Heating up time approx. | 0.5 hr* |

| Heating temperature | Max. 180 °C |

| Vacuum abs. | max. 50 mbar |

| Voltage | 380-410 V / 50 Hz / 3 Ph + N |

| Power consumption steam heating | 48 kW |

| Power consumption vacuum unit | 1,1 kW |

| Compressed air consumption approx. | 6 bar, Max. 50 l/min. |

| Required effective cooling capacity approx. | 40 kW |

| Cooling water consumption (8-12° C) approx. | 6.0 m³/hr |

| Width x depth x height approx. | 3.10 x 1.90 x 4.50 (always depending on configuration and changes) |

| Weight approx. | ~ 4,800 kg |

- All parts in contact with the product are almost exclusively made of stainless steel

- Automatic and continuous filling with contaminated solvents

- Level level is kept constant, thus largely constant distillation performance

- Conical stainless steel distillation vessel: Simple and complete emptying of the boiler by gravity and scraper insert.

- Perfect scraper system: scraper scrapes off the inside wall of the boiler, no readjustment necessary. Optimum tank cleaning guaranteed

- Modern steam heating integrated: Solvent heats up much faster than with thermal oil systems, No oil change more necessary = saves maintenance costs, no more encrusted heating elements, always constant heating output, no oil sludge in the system, no more boiler corrosion due to humidity in the thermal oil jacket

- Water cooling: Optimum condensation of the solvent vapours even at high ambient temperatures

- Switch cabinet IP54, with digital SIEMENS control S7 1200

- Switch cabinet with SIEMENS HMI colour TFT comfort panel with touch operation and process overview

- Automatic mode

- Auto-Stop: If dirty barrel or storage tank is empty, if temperature errors occur, if there is no water in the double jacket, if there is no cooling water available

- Constructed according to the latest European directives: Operational safety at a high level